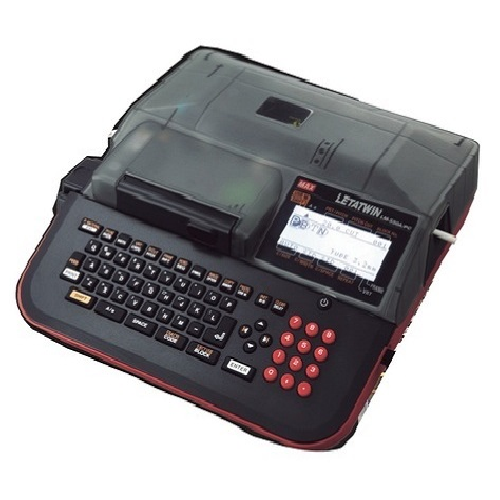

Industrial Ferrule Printing Machine

Product Details:

- Type Industrial Ferrule Printing Machine

- Material Metal body with ABS plastic components

- Capacity Continuous feeding, up to 200 ferrules per operation

- Printing Speed 25 mm/sec

- Computerized Yes

- Automatic Grade Automatic

- Plate Type Direct Ferrule Feed

Industrial Ferrule Printing Machine Price And Quantity

- 1 Unit

- 53100 INR/Unit

Industrial Ferrule Printing Machine Product Specifications

- Metal body with ABS plastic components

- Approx. 7.5 kg

- 5C to 40C

- 340 mm x 210 mm x 235 mm

- Integrated Keypad & LCD Display

- Continuous feeding, up to 200 ferrules per operation

- Approx. 210 mm

- Standard Desktop

- Yes

- Automatic

- AC 220V, 50Hz

- Direct Ferrule Feed

- Thermal Transfer Ribbon

- Industrial Ferrule Printing Machine

- 25 mm/sec

Industrial Ferrule Printing Machine Trade Information

- 2 Unit Per Day

- 3-4 Days

Product Description

- Offering new model LM 550 A lettering machine.

- Machine offering direct interface with PC as a printer.

- Also allows usage through Pen Drive.

- With provision of using it manually, it comes with internal memory of 250,000 (Two Lac Fifty Thousand) characters.

- Coming with support of hard carrying case (fitted with foam cushions from inside) for secure handling.

- Wide and backbit display support with high operational speed of 40mm/sec.

- Allows tube from 1.5mm to 8.00 mm ID to be printed with option of changing font size and density of printing.

- More easy and convenient to operate.

Technical specification

Name | MAX ELECTRONIC LETTERING MACHINE LM550A/PC |

Dimensions | 295 (W) x 293 (D) x 94 (H) mm |

Weight | 2.4kgs |

Printing Method | Thermal Transfer Method (300dpi) |

Display | LCD Dot Matrix: 64x160 pixel (Backlit) |

Printing Speed | 40mm / sec (Standard) 20mm / sec (Low Temperature mode) |

Maximum Printing Length | Tube: 20mm; Tape: 5mm By multiple copy printing , maximum 30 copies, up to Tube 100m, Tape 7m |

Maximum Number of Characters to Input | 5000 characters / file |

Character Size | 1.3, 2, 3 4, 6mm height |

Usable Tube | Ø 1.5mm ~ 8.0mm (PVC Tube) Ø2.0mm~6.5mm (Heat Shrinkable Tube |

Usable Tape | Width 5, 9, 12mm (MAX genuine Tape) |

Versatile Marking Capability | I D Plates , Oval Tubes. |

Tube Cutting Method | Auto half cut, Manual full cut |

Internal Memory | 250,000 characters (Maximum 50 files) |

External Memory | USB Memory |

Interface | USB 2.0 full speed |

Power Consumption | Max 30W |

Operating Environment | 10°C - 35°C |

High-Efficiency Ferrule Marking

Achieve up to 200 ferrule markings per operation with this automatic machine, delivering industrial-grade throughput thanks to its direct feed mechanism. Its consistent 25 mm/sec printing speed ensures productivity on large-scale cabling projects.

Integrated Intelligent Controls

The built-in keypad and LCD display streamline the printing process, allowing for real-time adjustments and monitoring. Operators benefit from straightforward, computerized control, reducing setup time and minimizing errors.

Durable and Adaptable Design

A metal body with ABS plastic components ensures the machine withstands demanding environments. Compact desktop dimensions and a moderate weight make it suitable for varied workshop or factory settings across India.

FAQs of Industrial Ferrule Printing Machine:

Q: How does the Industrial Ferrule Printing Machine operate?

A: The machine uses a direct ferrule feed plate to continuously supply ferrules for printing. Controlled via an integrated keypad and LCD display, it utilizes thermal transfer ribbon technology for precise, durable markingall governed by computerized automation.Q: What materials and capacities can this ferrule printer handle?

A: It is built with a metal body and ABS plastic parts, enabling it to process up to 200 ferrules per operation. The machine is suitable for standard ferrule types used in industrial wiring and cabling applications.Q: When is this printer most beneficial for industrial use?

A: This device is especially advantageous during projects requiring rapid, high-volume ferrule markingsuch as large electrical installations or cable assembly lineswhere consistent, clear identification is crucial.Q: Where can this ferrule printer be installed or utilized?

A: With its compact, standard desktop design and moderate weight, the printer can be installed in electrical workshops, manufacturing plants, or any setting requiring on-demand, professional ferrule printing.Q: What process does the machine use to ensure high-quality printing?

A: It employs advanced thermal transfer ribbon ink, producing sharp, permanent prints directly onto ferrules as they are fed through at a steady rate. This process ensures high durability and legibility under various operating conditions.Q: How is the machine controlled and monitored during usage?

A: Operators manage the printing process through the integrated keypad and monitor status or final output on the LCD display, enabling real-time adjustments and reducing the likelihood of errors.Q: What are the key benefits of using this Industrial Ferrule Printing Machine?

A: Key advantages include speedy, automated operation, reliable print quality, user-friendly controls, and a sturdy buildmaking it a valuable asset for exporters, importers, manufacturers, and suppliers in India seeking efficient cable identification solutions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Ferrule Printing Machine' category

|